You won’t find any pickup manufacturer who will reveal his “secrets”. Otherwise they would counteract their voodoo magic, which was specifically hyped for industrial marketing.

On the other hand, I am not afraid to show you the different steps of my handwork.

Which kind of pickup am I goin´ to make?

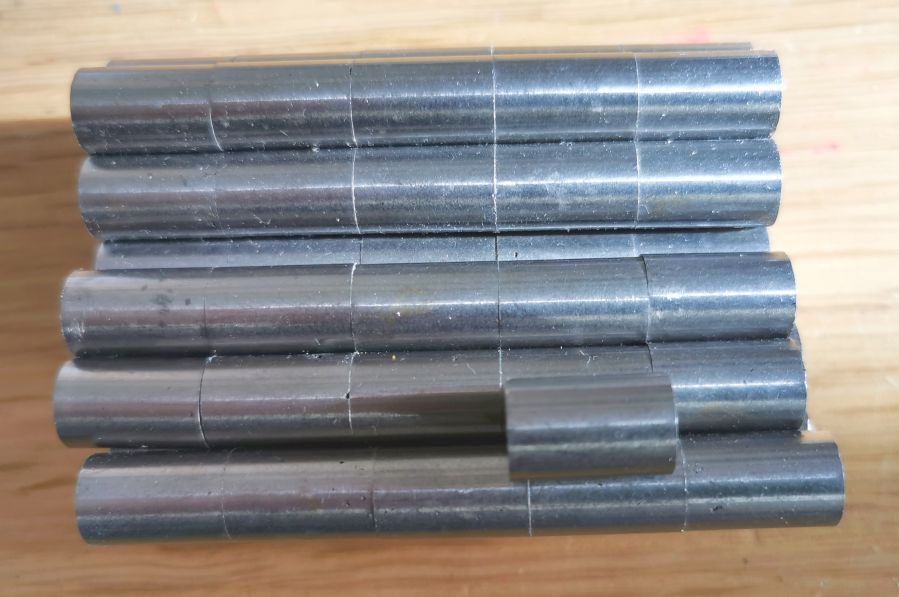

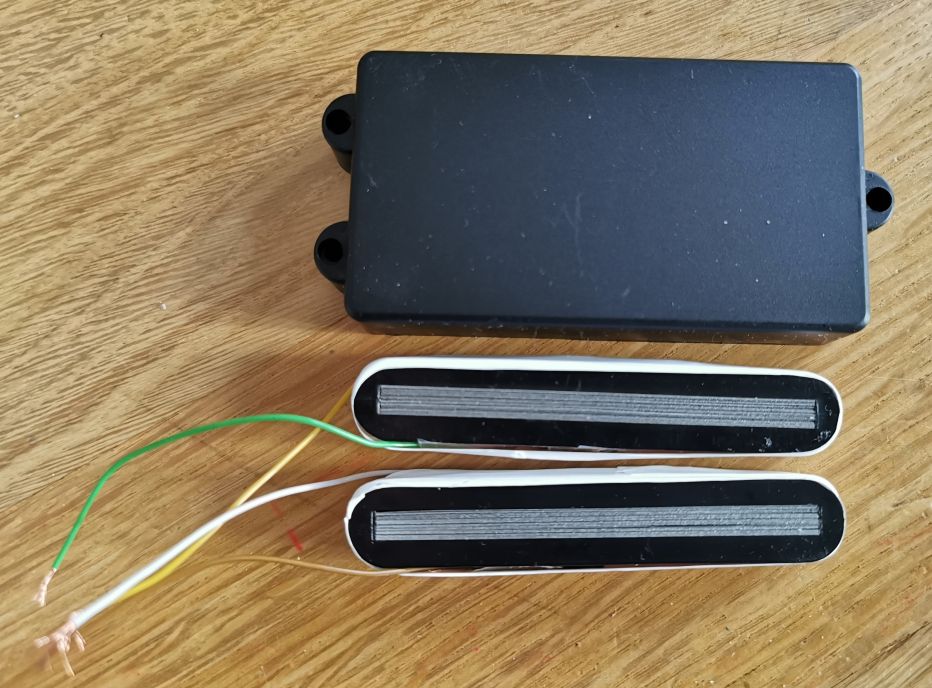

Selecting from different kinds of magnets and matching them. (alnico5, ferrite bar, ferrite slugs, FeSi-blades or steel-rods with alnico5 or neodym)

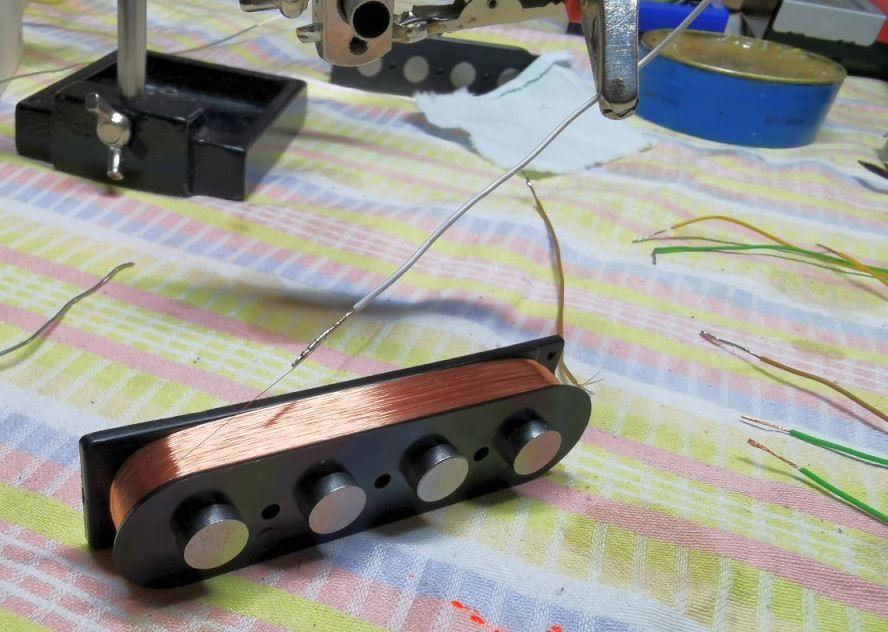

the procedure of making pickups – coils

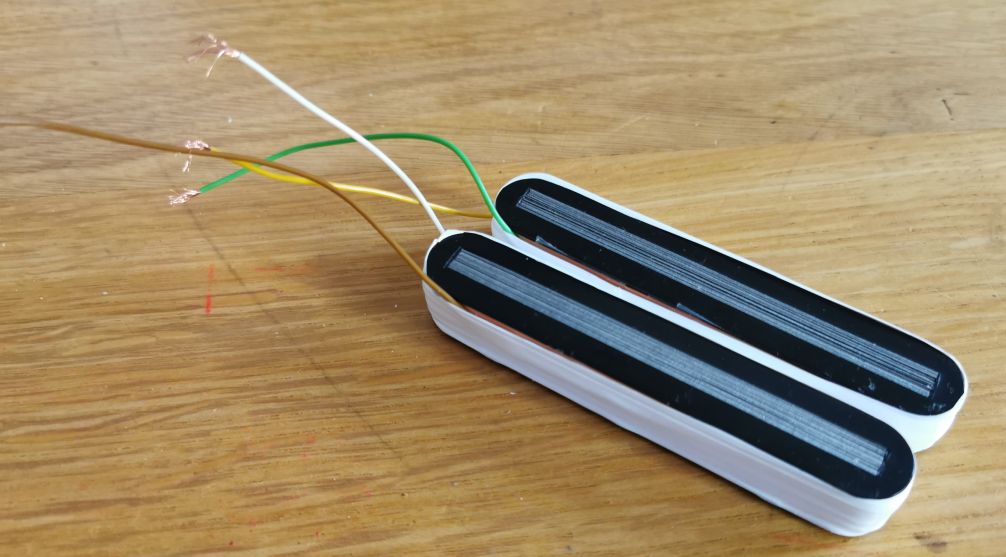

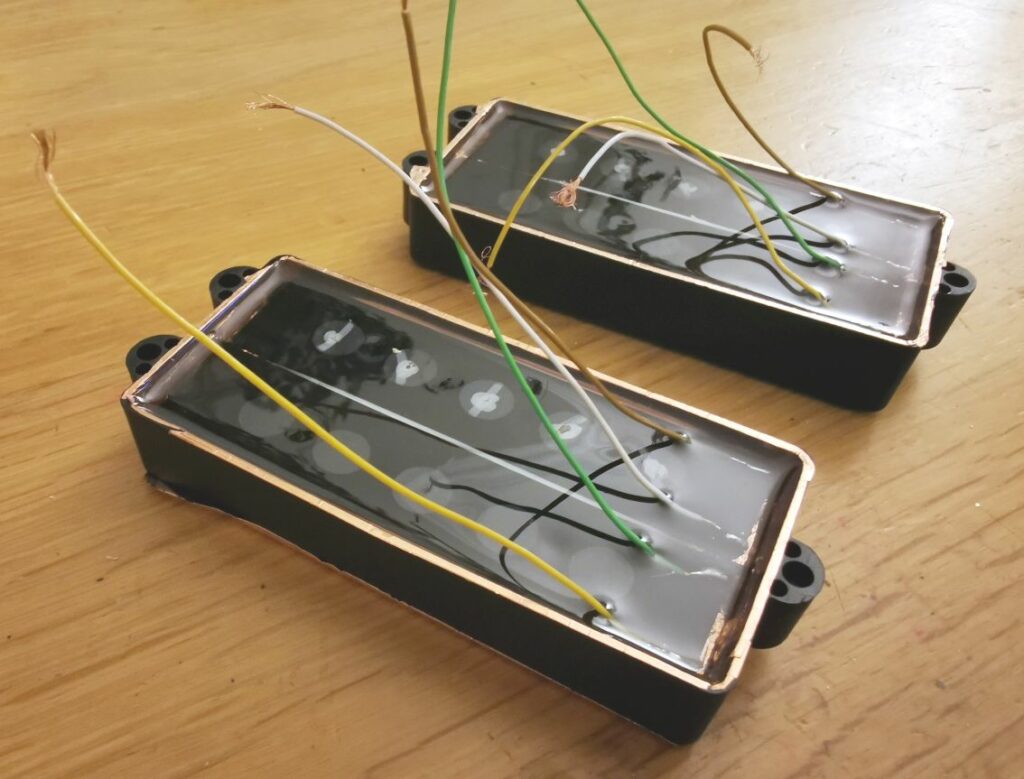

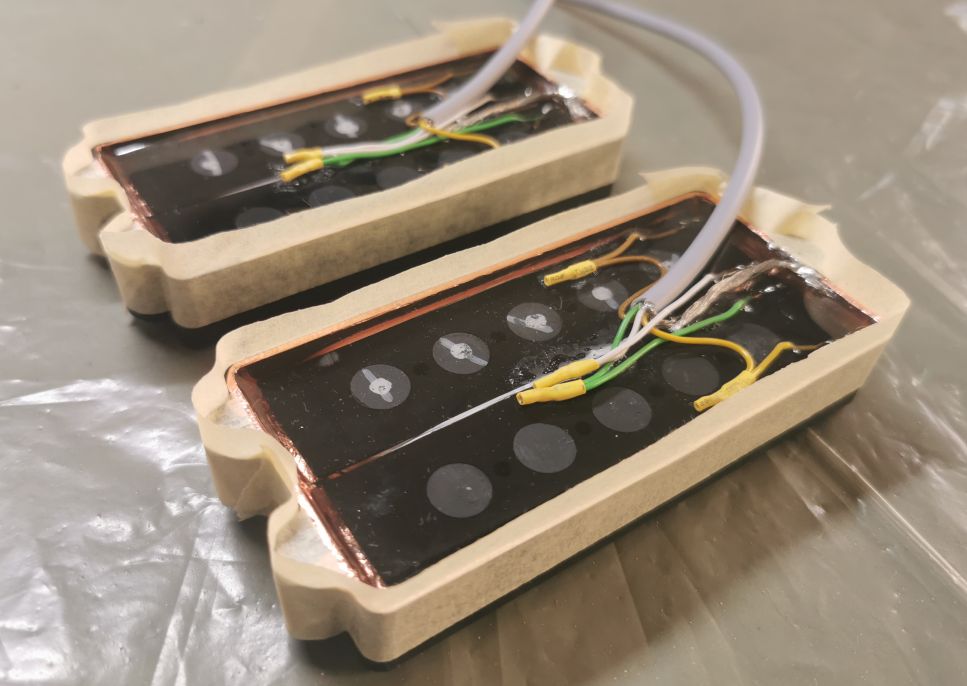

finish work – the pickups´s getting ready

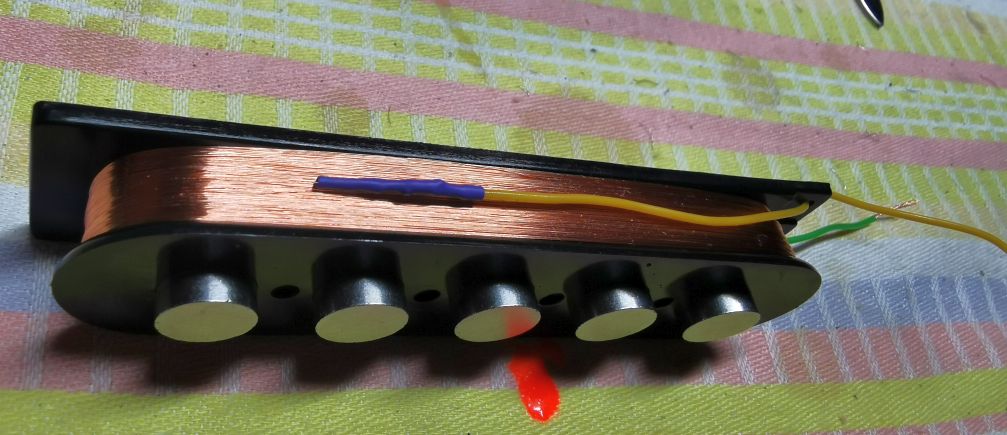

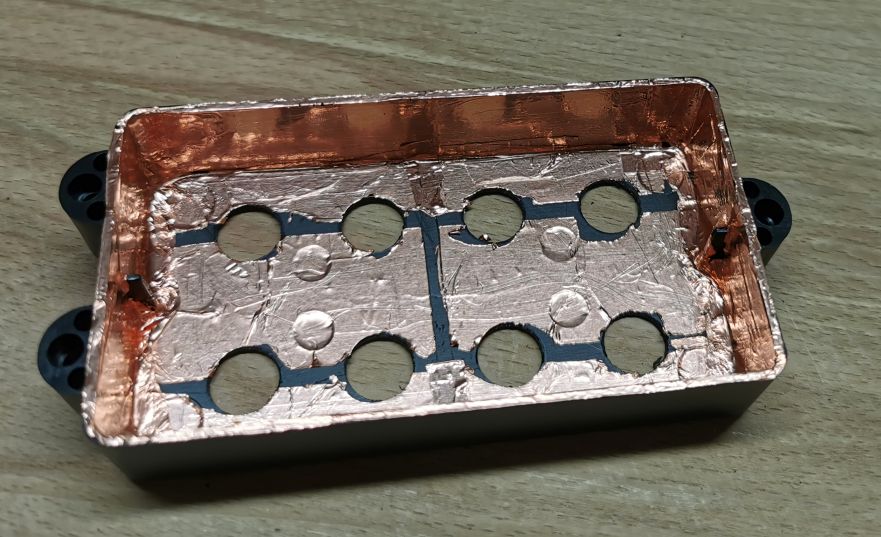

Since the first epoxy layer that surrounds the coils is extremely thin and leakage from the pole pieces cannot be prevented, the front must be covered with well-sealing copper foil so that as little epoxy as possible gets onto the pickup surface.

The copper foil is removed after the epoxy has cured moderately.

Finishing – no voodoo, just meticulous work!

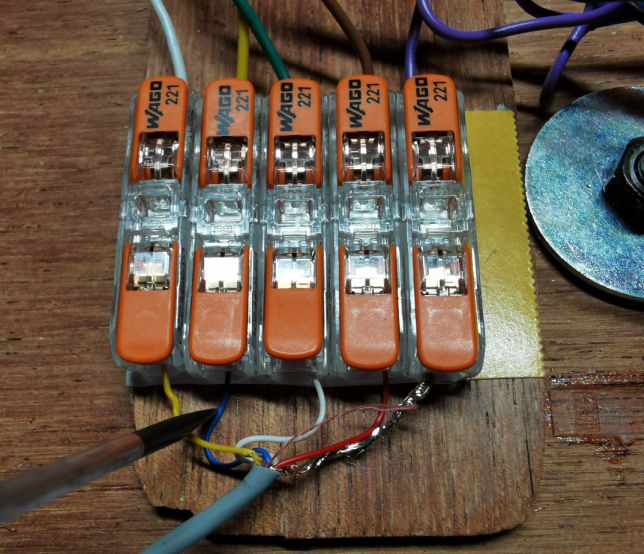

The wires get connected to the pickup-cable and the cable´s shield gets solded to the copper-shield of the pickup-cover for opt. ground and max. noise avoidance so that “noiseless pickup” lives up to its name..

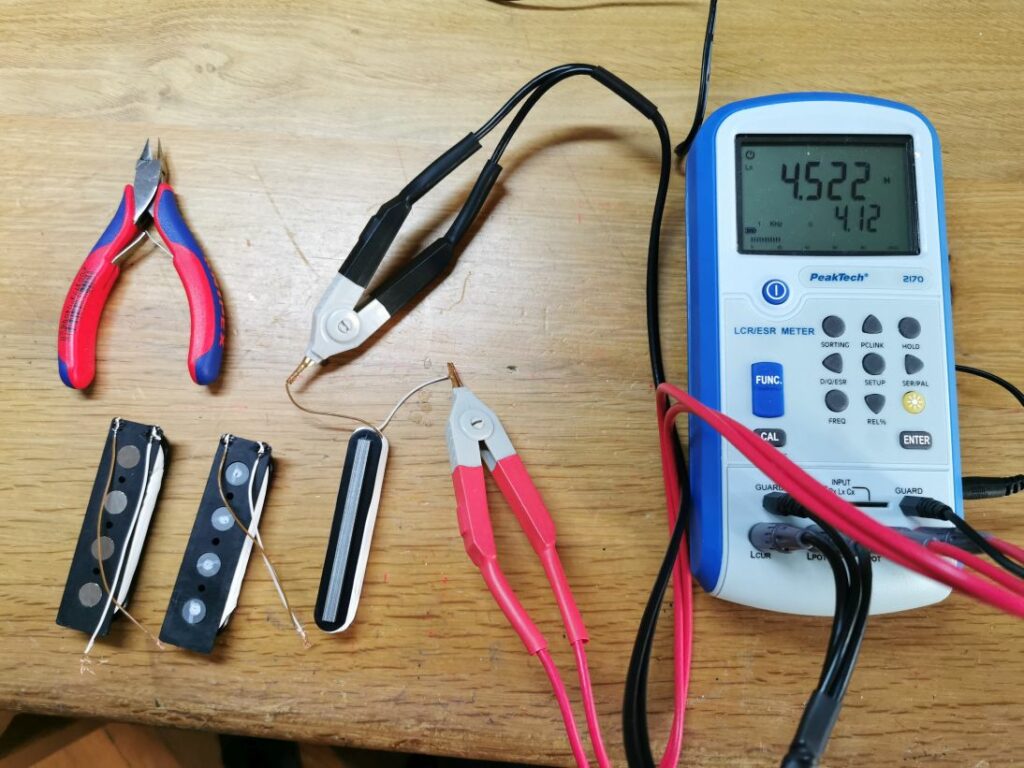

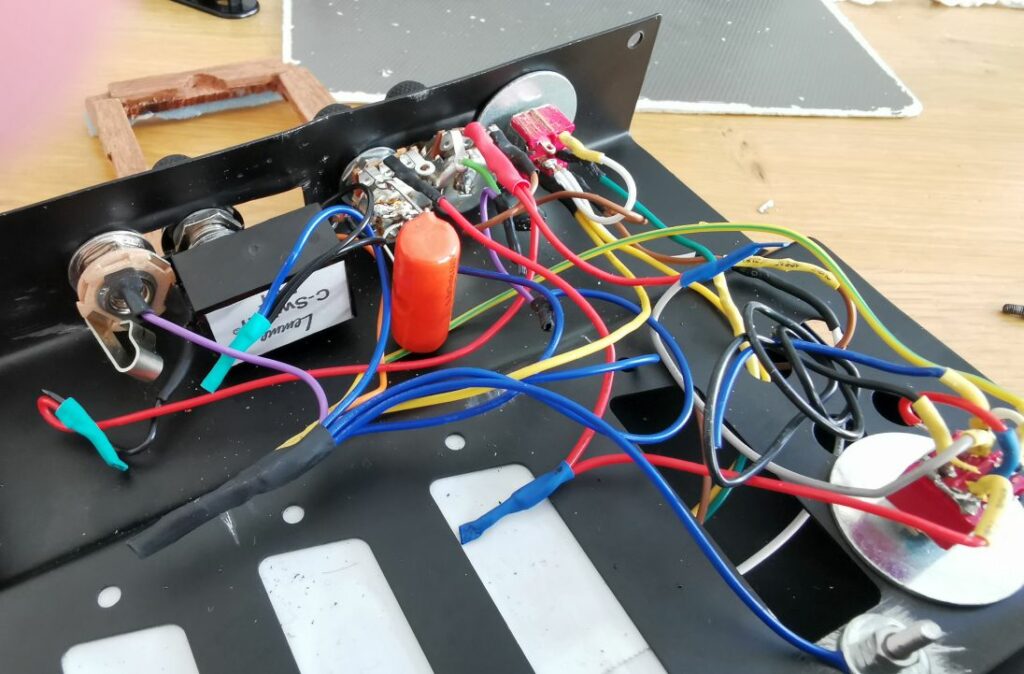

quality assurance – conventional or C-switch (6 different capacitors) or mixed

finally for sale!